Site Search

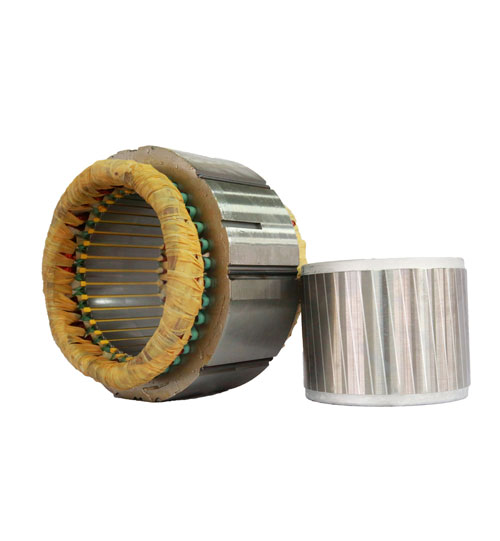

What is the difference between new energy motor and industrial motor?

Many people ask what is the difference between new energy motor and industrial motor? On the whole, the new energy motor and industrial motor of electric vehicles are a kind of motor, and the theory and method of classification and control are the same. And different from the industrial application of the motor is that the new energy motor used for electric vehicles usually requires frequent start and stop, rapid dynamic response, low speed constant torque operation and overload capacity is strong, the speed range is wide, can run in four quadrangles, fully meet the car running function at the same time should also meet the comfort of driving, adapt to the environment ability.

Compared with the drivers of industrial motors, the drivers of electric vehicles new energy motor have great differences in size, working environment, reliability, power density, cooling mode and other aspects. The basic requirements of electric vehicles new energy motor drive technology are summarized as follows:

1. Strict volume requirements and weight requirements: because it is a vehicle, so this aspect is outstanding. Ordinary industrial motors do not have such strict requirements for volume size and weight, generally to meet the industrial objectives as the first purpose. The size and weight of electric vehicles determine the dynamic performance and driving experience of the vehicle, which directly affects the quality of the product. Therefore, the difficulty of automobile new energy motor is to improve the power weight density and power volume density. The smaller, lighter and more powerful the motor, the better.

2. Unique torque characteristics: Super high torque is required at starting or low speed, and the car speed is pumped up to the desired speed in a very fast way. General industrial motors do not have such a high starting speed requirement. At the same time, enough power needs to be provided at high speeds so that the car can cruise at high speeds.

3. Wide speed range: the highest speed may be 4 times or higher than the base speed of the motor. At present, the best solution for electric vehicles is to leave out multi-gear transmission and only use fixed gear sets. In this way, the wider the speed range of the motor is required. This is a very big test for the power electronic governor.

4. Full range efficiency requirements: Unlike electric locomotives powered by a pantograph, electric cars are powered by batteries, and their cruising range depends entirely on motor efficiency. For every 1% increase in motor efficiency, cruise range can be increased by 1%. So the efficiency of the motor is very high. Can a little higher, is victory, every bit of energy to optimize.

5. High reliability and stability in the vehicle operating environment: a high degree of safety should be ensured under any circumstances, especially controllable failure mode.

6. Low noise: including electromagnetic noise and audio noise, to meet the needs of vehicle electromagnetic compatibility and driving comfort.

7. Reasonable cost: Cost remains a major barrier to the adoption of electric vehicles.

The main indexes to evaluate a motor drive system are external characteristics (maximum output torque and speed), constant power speed regulation range, drive system efficiency distribution diagram (not a point of efficiency, nor a single motor body or controller efficiency), drive system power density and torque density, etc.