Site Search

Routine maintenance of permanent magnet motors Routine maintenance and maintenance of permanent magnet motors

Because of the continuous development and utilization of resources, the utilization frequency of permanent magnet motor is also increasing. The motor industry ushered in the spring of development, and gradually realized the social utilization value of the motor. However, because the permanent magnet motor at work, the use of load is too large, so the permanent magnet motor will also present failure, if the problem is solved repeatedly, it will leave a lot of insurance risks. It is believed that to reduce the frequency of permanent magnet motor failure, in order to possibly protect the use of users, with the abnormal operation of permanent magnet motor, so we need to carry out maintenance and maintenance of permanent magnet motor on schedule. The following motor to introduce to you, permanent magnet motor daily maintenance and care.

First of all, when the machine presents problems, the first thing is to cut off the power supply in time, otherwise it is very easy to present insurance incidents, the most common is the high voltage electric shock, the best way is to cut off the power supply and wait for professional maintenance personnel to repair.

Then it is necessary to check and maintain the permanent magnet motor on schedule, and it is necessary to clean the dust and oil stains of the mechanical and electrical machinery in time. Check the work includes: 1. Whether the line is loose or damaged, if there is, it must be replaced in time. 2. Check whether the fixing place is firm. 3, the rest of the local electricity is good contact, if not, you need to check lubricant or machine is not clean and other related problems, and then careful investigation. 4. The most important part to check is the electrical and mechanical insulation ability. Once the insulation function presents problems, the result is very important, which will not only pose a threat to the personal insurance of personnel, but also destroy the rest of the equipment. So these careful matters are the group to check often.

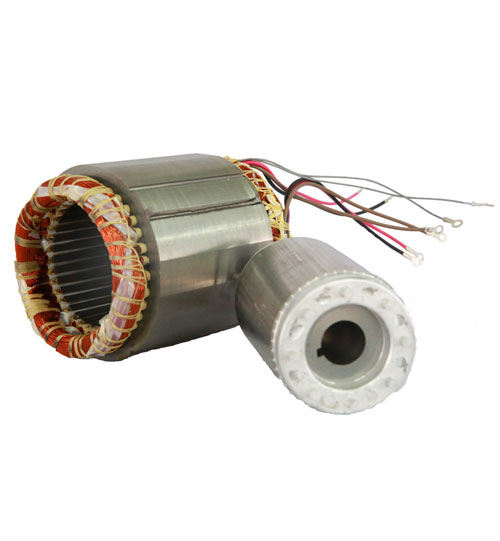

Permanent magnet motor Permanent magnet motor Permanent magnet motor refers to the electric motor with a rated voltage above 1000V. The voltage of 6000V and 10000V is often used, because the power grid in foreign countries is different, there are also voltage levels of 3300V and 6600V. Permanent magnet motor is generated because the motor power is proportional to the product of voltage and current, so the low-voltage motor power increases to a certain level (such as 300KW/380V) current is allowed by the wire the limit of ability is difficult to do, or the cost is too high. Need to achieve high power output through progressive voltage. High voltage piezoelectric high voltage permanent magnet motor advantages machine advantages machine advantages machine advantages is large power, strong impact ability; The fault is the inertia, starting and braking are hard.

Permanent magnet motors can be used to drive a variety of different machines. Such as compressor, water pump, crusher, cutting machine, transport machinery and other equipment, for mining, machinery industry, petrochemical industry, generators and other industries as the original idea. To drive the blower, coal mill, rolling machine, hoist electric motor should be indicated in the order of use and skill request, take special design to ensure solid operation. According to the actual method: the motor capacity is greatly less than the power supply capacity and below 1000KW can be directly started, then the impact current is 3-6 times the rated value. In order to avoid excessive impulse current, starting methods to reduce the starting current must be considered for large motors: series reactance starting, frequency conversion starting, hydraulic coupling starting and other methods.

There are many simple, the price is very different. Because the voltage is high, the current impact is large, the motor manufacturing must be satisfied with the overvoltage request, the insulation level request is higher. And maintenance

Basic requirements for daily maintenance of permanent magnet motor:

1. The power supply voltage of the motor should be within the rated range of ± 5%, frequency ± 1%.

2. Whether the working current is deformed (three-phase current should be flat ±10%, and cannot exceed the rated current operation).

3. The local temperature rise can not exceed the delimited request (individual large motor has temperature control sensor).

4. Watch out for malformed sound when running.

5. Carefully completed the handover and record of post requests, so as to investigate the cause of the incident afterwards.

In order to protect the permanent magnet motor malformation work, in addition to the use of malformation according to the operating procedures, careful malformation supervision and maintenance in the process of operation, should also be checked on schedule, do a good job of permanent magnet motor maintenance. This may eliminate some maladies in time, avoid failure and ensure the solid operation of the motor insurance. The time interval of scheduled maintenance can be determined according to the situation of the motor.

Regular maintenance of permanent magnet motor is as follows:

1. Clean the motor. Remove dust and sludge from the outside of the motor frame in time. If the use of environmental dust more, z is best to clean once a day.

2. Check and clean the motor terminal. Check whether the wiring screws of the junction box are loose or burned.

3. Check the fixed local screws, including anchor screws, end cover screws, bearing cover screws, etc. Tighten the loose nut.

4, check the transmission device, check whether the pulley or coupling force, damage, whether the device is strong; Whether the belt and its buckle are in good condition. Explosion-proof motor A type of motor that can be used in inflammable and explosive places and does not produce sparks during operation. Explosion-proof motor is mainly used in coal mine, oil and gas, petrochemical and chemical industries. In addition, it is also widely used in textile, metallurgy, urban gas, transportation, grain and oil processing, paper making, medicine and other sectors.

5. The starting equipment of permanent magnet synchronous motor should also wipe the external dust and wipe the contact in time, check whether the wiring parts have burn marks, and whether the grounding wire is good. Explosion-proof motor A type of motor that can be used in inflammable and explosive places and does not produce sparks during operation. Explosion-proof motor is mainly used in coal mine, oil and gas, petrochemical and chemical industries. In addition, it is also widely used in textile, metallurgy, urban gas, transportation, grain and oil processing, paper making, medicine and other sectors.

6, bearing inspection and maintenance. Bearings should be cleaned and replaced with grease or lubricating oil after a period of time. Cleaning and oil change time, should be with the working condition of the motor, working environment, cleaning level, lubricant varieties, half of every 3-6 months, should be cleaned once, new grease. When the oil temperature is higher, or the environmental premise is poor, the motor with more dust should be cleaned and changed often.

7, insulation inspection. Explosion-proof motor A type of motor that can be used in inflammable and explosive places and does not produce sparks during operation. Explosion-proof motor is mainly used in coal mine, oil and gas, petrochemical and chemical industries. In addition, it is also widely used in textile, metallurgy, urban gas, transportation, grain and oil processing, paper making, medicine and other sectors. The insulation ability of insulation materials varies with the drying level, so it is very important to check the drying of motor windings. The electrical insulation will be destroyed if the working environment of the motor is wet and there are corrupting gases in the working room. The most common fault is the winding grounding fault, that is, the insulation damage, so that the live part and the housing and other metal parts should not be charged, such a fault will not only affect the motor malformation, but also endanger the life insurance. Therefore, the motor in use, should often check the insulation resistance, but also careful to see whether the motor housing grounding is strong.

8. In addition to the scheduled maintenance of the motor according to the above contents, it should be overhauled once after one year of operation. The goal of overhaul is to conduct a thorough and comprehensive inspection and maintenance of the motor, supplement the missing and worn parts of the motor, completely eliminate dust and dirt inside and outside the motor, check the insulation, clean the bearing and check its wear condition. Invent problems and deal with them promptly.

Individually, the working life of permanent magnet motor is very long only if the use is correct, the maintenance is appropriate and the invention failure is handled in time.